In a shrink sleeve labelling machine sleeves cut from a web of side-seamed plastic film are placed over a container and then shrunk by heat to fit tightly on the container profile. In a less common variation sleeves are stretched, placed over the container and then released to grip the container profile.

Most sleeve labelling machines have an inline configuration as shown in the animation below. Rotary machines also exist, particularly for application of stretch sleeve labels at higher speeds.

This animation shows a basic machine operation with intermittent film feed and labels cut on the machine. Machines with very high operating speeds use pre-perforated labels and continuous film feed. The film feed section normally includes a buffer zone (not shown) to maintain production during reel changes.

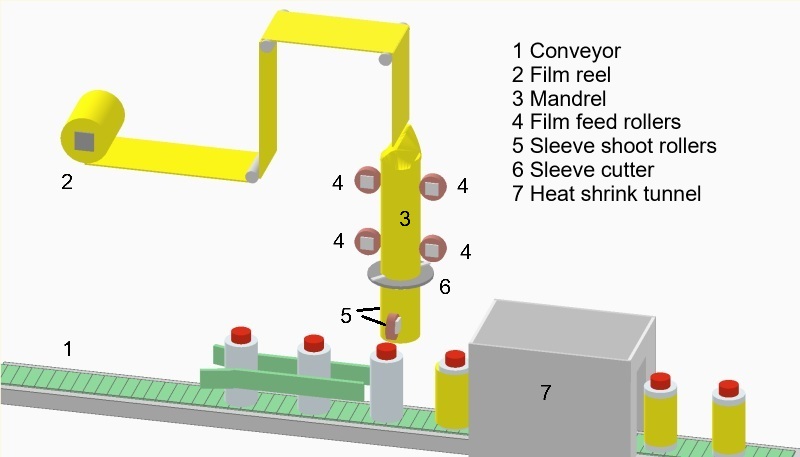

Above - Basic operation of an inline machine applying sleeve labels

Below - Principal machine components for application of sleeve labels